- Sawing Machines

- Compact sawing machines

- Universal sawing machines

- Production Bandswing Machines

- Production Circular Sawing Machines

- Sawing Systems

- Storage Material Handling Solutions

- Storage-Sawing Automation

- Smart Solutions

- KASTOlogic

- KASTOmobile

- KASTOoptisaw

- KASTOapp

- Integrated Technologies

- KASTOenergysave

- KASTO VisualAssistance

- Service Support

KASTO Machinery & Systems (Taicang) Co., Ltd.

Hotline: 0512-53208750

Email: sales@kasto.cn

Email: service@kasto.cn

Address: No. 82 East Beijing Road, Taicang City, Jiangsu Province

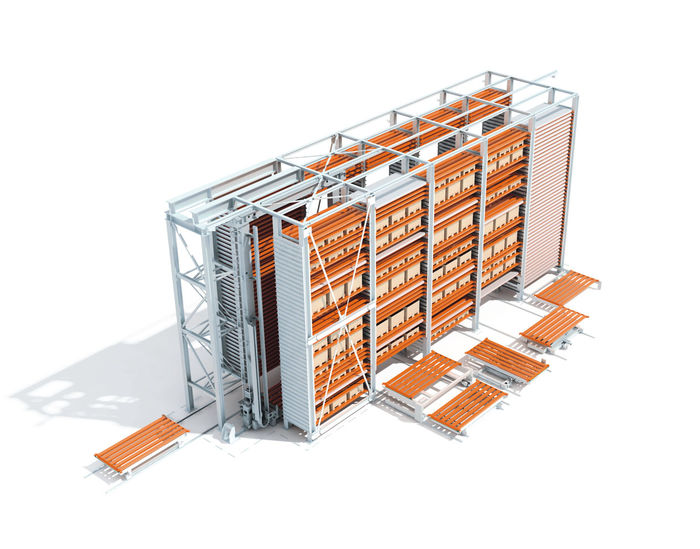

UNITOP

Ideal space utilisation, safe storage management

Computer controlled, the UNITOP allows a perfect overview of the inventory at any time and is able to deliver the requested bar stock every 120 seconds – depending on system height – to the unloading station. Individually tailored in/out stations ensure the adaptation to the company-specific material flow. With the (optional) integration of an automatic bar separator and a connection to a KASTO CNC-saw, a flexible, profitable manufacturing system is created. The UNITOP Bar Storage System is a highly efficient and extremely reliable, fully automated system requiring a minimum of personnel.

Your benefits at a glance

Fast access to self-supporting cassettes

Fully automatic operation with minimal per-sonnel requirements

Perfect overview of stock

Individually designed infeed/outfeed stations enable adjustment to a specific material flow

In conjunction with an undercarriage, the UNITOP bar storage system turns into a fast pick-ing system

UNILINE

This storage system can be installed as a stand-alone unit within existing buildings. Upon request, the steel structure can be designed as a rack-supported silo construction with wall and roof enclosure.

The UNILINE offers different system pallets for flat and bulky storage goods where different formats can be combined.

Typical applications are: Sheet metal storage systems for commissioning in steel distribution, Interface to sheet metal processing machines for virtually unmanned Operation, Logistics center to store crates, tools and other materials to interface different work areas in manufacturing facilities.

Your benefits at a glance

Highest storage density due to effective space utilization for smallest floor-space use

Fast pallet changeover times due to fully automatic operation ensure short processing times with reduced personnel

Clear storage management ensures better safety and easier planning

Optimum inventory control due to perpetual inventory management

Fully automatic handling for fast commissioning of all types of orders in metal distribution

苏公网安备 32058502010690号

苏公网安备 32058502010690号